IP, EMC and environmental protection for embedded computer

Companies today demand the needs for task specific applications. The use of embedded devices has facilitated in the every day chores of specialized operations. These systems provide a dynamic collaboration between software and the world. As a result, embedded systems have delivered speed, reliability and efficiency to everyday demands. However, most industrial applications demand more durability in these products to be able to withstand the harsh environments that can only be successful with industrial grade protections.

Many industrial applications that involve embedded computers are used for POS systems, transportation, kiosks, surveillance, and factory and building automation. Environments like these can present temperature changes, harmful chemicals, corrosion, dust, liquid spillage, and other things that can be potentially detrimental to theses devices. Below is an analysis that shows the importance of the industrial grade protection system.

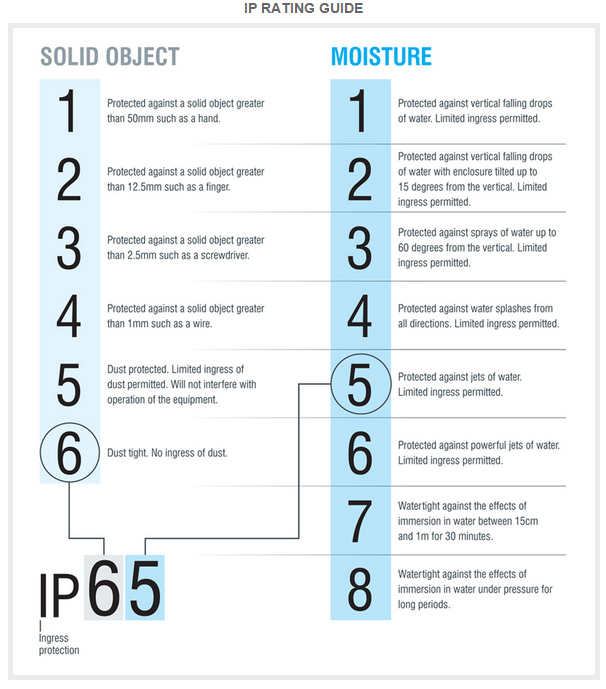

IP protection

Ingress protection or IP protection is a critical protection to include in embedded systems. It brings different levels of protections concerning specific tasks from the harsh environments in factories to military operations. This degree of security brings a more stable enclosure to the system as a whole. The ingress protection allows a system to be invulnerable to dust, other solid objects and water. For example, an IP65 rating allows protection from water sprays from all directions and dust. However for military standards, an IP67 rating would be more suitable as it allows the device to be completely invulnerable to dust and even submerged under water for a short amount of time.

Electromagnetic Compatibility (EMC)

The industrial grade protection also provides an electromagnetic compatibility. This simply means that embedded systems are able to operate in an environment without intruding on other electrical devices and vice-versa. EMC contains two categories: electromagnetic susceptibility (EMS) and electromagnetic interference (EMI).

Electromagnetic susceptibility, according to the Dictionary of Engineering is, “The ease with which a component, circuit, device, piece of equipment, or system may suffer a degradation in performance, a malfunction, or a failure, due to the influence of electromagnetic energy”. EMS introduces a type of interference: Electrostatic Discharge (ESD). ESD occurs when there is a electrical shortage when two electric charged objects come together.

Electromagnetic interference is, “An electromagnetic disturbance which brings about a degradation in performance, a malfunction, or the failure of a device, piece of equipment, or system. electromagnetic interference can be produced by countless sources, such as microchips, lightning, power lines, and radio frequency signals. Devices such as shields and filters are utilized to minimize or prevent its effects”. Industrial grade protection eradicates the harmful effects of electromagnetic interference and energy.

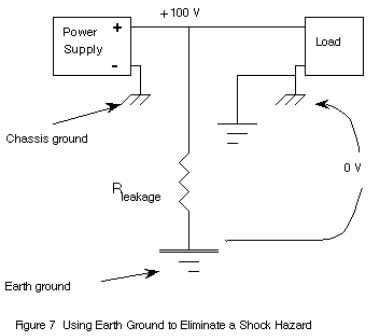

Grounding Electrical Protection

To prevent excessive electricity like EMI from interfering with the device, a ground lightning and electrical protection is critical for embedded systems. To prevent lightning and other voltages from entering in the computer, these protection system implants heavy rods in the ground that safely redirects the path electrical currents.

Industrial Grade Environmental

Protection Operating embedded systems, whether located in factories, outdoor settings and mission critical tasks, require a tolerance of wide ranging temperatures. Industrial grade protection equips embedded systems with a tolerance to freezing and hot temperatures and low to high humidity as well. Harsh environments can also leave embedded devices to random vibrations and shock when items are being transported and even dropped. Military grade embedded devices are also available for even more demanding tasks that meet the standards by the United States Army’s Developmental Test Command. If devices do not have shock and vibration protections, internal components can overtime lead to electrical shortages and damaged components.